Performing Repairs on Concrete Surfaces

When it comes time to repair concrete surfaces, specialized spackling compounds for cosmetic corrections become essential on every construction site and in prefabrication plants.

The use of spackles for concrete cosmetic work is not dependent on the class of concrete. Even high-quality exposed concrete surfaces may require precise corrections, such as when the natural raw materials used result in color differences in the concrete.

Over time, specialists in concrete cosmetics develop their own methods for carrying out cosmetic work. Since concrete cosmetic tasks vary widely, the tools used can also differ depending on the specific situation and requirements. It is important to understand that selecting the right tools and techniques is crucial to achieving the desired results when repairing concrete surfaces.

What to Use for Concrete Cosmetics?

Concrete spackles are invaluable tools for transforming defective surfaces into flawless exposed concrete. Defects such as chips, cracks, pores, shrinkage cavities, color differences, or stains can be easily and quickly turned into high-quality surfaces.

MC Concrete Cosmetics Spackle Range

The MC range of concrete cosmetic spackles includes two broad groups of products with various properties and colors. These spackles are characterized by:

- Optimal adhesion to concrete surfaces: Ensures the spackle firmly adheres to the substrate, creating a durable and aesthetic layer.

- Easy application: Simplifies the process of making cosmetic corrections.

- Resistance to frost and UV radiation: Maintains quality even under harsh weather conditions.

- Usability in extreme weather conditions: With appropriate additives, the spackles remain effective in the most challenging environments.

Color Range and Customization

The color palette of cosmetic spackles is comprehensive, and mixing different shades allows for achieving the desired tone. Additionally, with special additives, it is possible to create custom colors, offering flexibility in adapting spackles to specific concrete cosmetic projects. These spackles are indispensable for improving the appearance and quality of concrete surfaces.

MC-Powertop G

A coarse-grained spackle with extended workability time:

- Application temperature: From +15°C to +35°C.

- Suitable for small surfaces.

- Superficial corrective work: Ideal for minor surface adjustments.

- Repairs chips, edge damage, and similar defects.

MC-Powertop F

A fine-grained spackle with extended workability time, designed for precision work on high-quality exposed concrete surfaces:

- Application temperature: From +15°C to +35°C.

- Surface spackling: Ideal for small pores, shrinkage cavities, and cracks.

- Precise surface finishing: Ensures smooth and polished results for premium-quality exposed concrete.

MC-Powertop F

Features of MC-Powertop F

MC-Powertop F is a fine-grained spackle designed to meet the demands of concrete surface restoration and aesthetic enhancement. Below are its key features:

- Ready-to-use formula: The product requires only mixing with water, simplifying the application process significantly.

- Chemically enriched: Formulated with advanced chemical additives for enhanced performance.

- Weather and frost resistance: Ensures durability under varying environmental conditions.

- Durable color and UV-resistant pigments: Maintains surface aesthetics over an extended period.

- Layer thickness up to 6 mm per application: Suitable for precise and efficient surface correction.

- Ceiling application: Ideal for overhead work with excellent adhesion.

- Spray application option: Can be applied using spray equipment for large-scale projects (consult a technical advisor for details).

- Classification according to EN 1504-3, Class R1: Certified to European standards, ensuring reliability and quality for non-structural applications.

- Available in various shades: Offers flexibility to match specific color requirements.

- Low chromate content: Ensures compliance with safety and environmental regulations.

MC-Powertop F Fine

A very fine-grained spackle for precision finishing of high-quality exposed concrete surfaces:

- Surface spackling: Ideal for addressing small pores, shrinkage cavities, and cracks.

- Precise surface finishing: Ensures flawless results on premium exposed concrete.

MC-Powertop F fine

Features of MC-Powertop F fine

MC-Powertop F fine is a very fine-grained spackle tailored for precise concrete surface corrections and finishing. Its key features include:

- Ready-to-use formula: Requires only mixing with water, ensuring ease of preparation and application.

- Chemically enriched: Enhanced with advanced additives for superior performance.

- Weather and frost resistance: Durable under diverse environmental conditions, ensuring long-lasting results.

- Durable color and UV-resistant pigments: Retains aesthetic appeal over time, even under direct sunlight.

- Layer thickness up to 3 mm per application: Ideal for detailed and fine finishing.

- Ceiling application suitability: Designed to perform well in overhead repairs.

- Classification according to EN 1504-3, Class R1: Complies with European standards for non-structural applications, assuring high quality and reliability.

- Low chloramine content: Environmentally safe with reduced harmful components.

Application

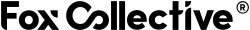

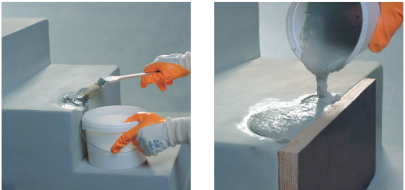

Coarse-grained fillers are applied with a trowel and then spread using a steel float. The easiest and most precise application is achieved with the use of a rubber float.

When performing cosmetic work on concrete, it is recommended to wear protective glasses and gloves.

Smoothing

To achieve a thin and smooth surface, the filler should be smoothed with the MC-Top Sponge, which is dual-sided. Moisten the sponge with a small amount of water and wring it out thoroughly. Excess water can cause discoloration or smearing of the filler.

Curing

To achieve a perfect surface, freshly applied filler should be protected from rapid drying caused by sunlight, wind, or other atmospheric influences. Special attention should be given to protecting the surface from rain for at least 7 days.

Fine-Grain Spackling for Small Areas

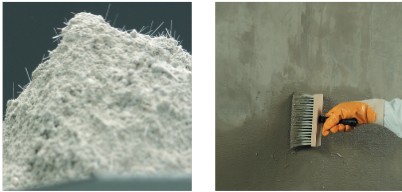

Filling Pores and Shrinkage Cavities

The substrate should be slightly moistened as described earlier. MC-Powertop F filler is perfect for filling even the smallest pores and shrinkage cavities. A rubber float is ideal for applying the filler.

Fine-Grain Spackling for Large Areas

Surface Finishing

MC-Powertop F filler is used not only for smoothing and repairing concrete surfaces but also primarily for finishing large surfaces and leveling color differences.

For an even smoother surface, it is recommended to use the very fine-grained filler MC-Powertop F fine. Alternatively, the MC-Quicktop filler can also be used for smoothing.

To achieve optimal surface finishes when working with fine-grained fillers, the surface should be wiped with the MC-Top Sponge. This will result in even smoother and more aesthetically pleasing surfaces.

For dusty or insufficiently load-bearing substrates, it is advisable to use the primer MC-Estrifan Grund T 15. Apply the material in a single layer, or for very absorbent substrates, in multiple layers using a roller. After priming, you can proceed with the filling process.

Coarse-Grain Spackling for Small Areas

Filling Bug Holes by Trimming Excess Filler with a Trowel

The original contours of concrete elements can be restored by trimming the excess filler with a trowel. Ensure that the filler is slightly set before cutting.

Filling Holes and Anchor Points

Anchor holes should be pre-wetted before being filled with the mixed filler MC-Powertop G. Excess material should be trimmed with a trowel for a smooth finish.

Color and Texture Matching with Fine-Grained Fillers

For slightly dried concrete surfaces, fine-grained fillers can be used to optimally match the color and texture to the original concrete.

Coarse-Grain Spackling for Large Areas

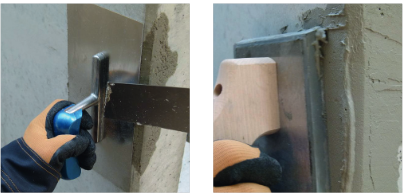

Leveling Surfaces with Fiber-Reinforced Fillers

The mixed MC-Top Primer bonding layer should be carefully rubbed into the pre-wetted surface. A wide brush is ideal for this purpose. MC-Powertop G extra filler is applied to the fresh, matte-damp bonding layer.

- Application Thickness:

- Single layer: 5 to 25 mm.

- Double layer: Up to 50 mm.

Advantages of Fiber-Reinforced Fillers

Fillers such as MC-Powertop G extra and MC-Powertop G ultra are reinforced with special fibers, making them ideal for leveling large surfaces effectively and ensuring durability.

MC-Powertop G ultra Application

MC-Powertop G ultra is applied directly to a matte-damp substrate without the need for a bonding layer.

- Application Thickness:

- Single layer: 6 to 40 mm.

- Double layer: Up to 80 mm.

For a second layer:

- Apply directly if the first layer is partially set.

- If the first layer is fully dried, apply the MC-Top Primer bonding layer before adding the second layer.

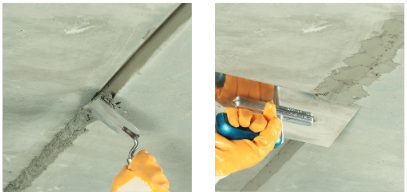

Filling Gaps Between Prefabricated Elements

Filling Gaps

MC-Quicktop Uni is applied using a trowel or spatula in a layer up to 20 mm thick onto a dampened gap between prefabricated elements. Leave a slight excess of the filler and smooth it while still fresh.

- For a wallpaper-ready joint:

Wait for the filler to set, then trim the excess with a trowel.

Lightly sponge the filled gap with a damp MC-Top Sponge to ensure a smooth finish. - Optional Additive:

By adding a synthetic additive like Repacryl to the mixing water, you can significantly enhance the adhesion of the filler to the substrate.

Applying Cosmetic Slurry

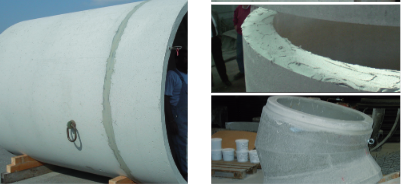

Slurry Application

Pipe joints should be dampened and then coated with a slurry applied using the MC-Top Sponge. The slurry is prepared by mixing the synthetic additive Repacryl with MC-Quicktop filler.

Filling Corner Cavities (Without Load Bearing)

Bonding Layer and Application of Coarse-Grained Fillers

- Bonding Layer

Apply MC-Top Primer as a bonding layer to a damp, matte surface. - Filler Application

While the bonding layer is still fresh, apply MC-Powertop G filler with a slight excess. This method is also effective for re-profiling damaged corners and edges.Trimming Corners

The contours of concrete elements can be easily shaped by trimming the excess slightly hardened filler. Use a trowel or appropriate cutting tool to refine the edges and achieve the desired profile.

Reprofiling with Fine-Grained Fillers

- Application of Fine-Grained Filler

To achieve the quality of fair-faced concrete, apply a layer of fine-grained filler MC-Powertop F or MC-Quicktop on the slightly dried coarse-grained filler. - Smoothing the Surface

For a smooth finish, lightly wipe the filler surface with an MC-Top Sponge.

Filling Corner Cavities (With Load Bearing)

Grinding

- Early Grinding Capability

Due to the very high initial strength of Reparoxyd SB/WG mortar, the surface can be ground just 30 minutes after application. - Adjusting Consistency

By reducing the liquid components, Reparoxyd SB/WG mortar can be prepared in a consistency suitable for troweling.

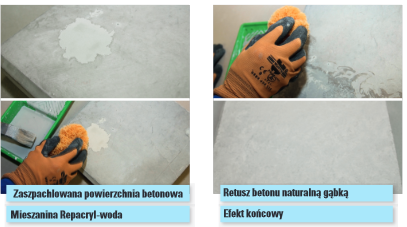

Concrete Retouching on Spackled Surfaces

Concrete Retouching on Spackled Surfaces

- Preparation

Retouching is possible only after the fine-grained spackle has completely dried. First, mix the Repacryl hellgrau synthetic additive with water and spread it on the surface using a natural sponge. - Adjusting the Mixture

Depending on the substrate, darken the mixture for each subsequent retouching step by adding Repacryl lichtgrau or betongrau. - Final Step of Retouching

By adding MC-Powertop F fine spackle to the Repacryl-water mixture, you can reduce gloss. Gentle polishing provides an aesthetically uniform appearance to the concrete surface.

Concrete Retouching on Non-Spackled Surfaces

Retouching on non-spackled surfaces can also be performed as described above.

Concrete Retouching on Surfaces Exposed to External Factors

- Hydrophobic Protection

Once the retouch layer has completely dried, coat the surface with a hydrophobic agent, such as Nisiwa C, Nisiwa SN, Nisiwa L, or MC-Color Proof. - Ensuring Uniform Absorption

Apply the hydrophobic layer over the entire sections of the surface to equalize absorption and protect the surface against external influences.

Joining Construction Elements with SX 481 E Spackle

Substrate Inspection

Before applying SX 481 E spackle, the substrate parameters must be checked.

- Tensile strength: Minimum of 1.5 MPa.

- Residual moisture: Must not exceed 4%.

Substrate Preparation

The substrate must meet the following requirements:

- Clean: Free from dust, grease, and any other materials that could hinder adhesion.

- Dry: Ensure no residual dampness remains.

- Stable: Must be load-bearing and free from loose elements.

Emcefix floor

Features of Emcefix Floor

- Cement-Based: Emcefix Floor is formulated on a cement base, ensuring durability and reliability.

- Ready-to-Use: The product is ready to use—simply mix it with water. This makes application straightforward and quick.

- Easy and Fast Application: Designed for efficient handling, it simplifies the repair and finishing process.

- Stress-Free Hardening: It hardens without causing internal stresses or cracks, ensuring a smooth and flawless finish.

- Wear Layer: Can serve as a durable wear layer for high-traffic areas.

- High Abrasion Resistance: Withstands significant wear and tear, making it ideal for heavy-duty applications.

- Forklift Traffic Compatibility: Can be loaded with forklift traffic, highlighting its robustness for industrial use.

- Frost and De-Icing Salt Resistant: Certified frost and salt resistance according to CEN/TS 12390-9 standards, ensuring long-lasting performance in challenging environments.

- EN 1504-3 Classification: Classified under EN 1504-3 as meeting principles 3 and 7, and methods 3.1, 3.3, 7.1, and 7.2, achieving R3 class.

- Versatile Application: Suitable for both indoor and outdoor use, making it a versatile solution for various concrete repair needs.