How to Waterproof a Well?

grudzień 8, 2022

Waterproofing in Kraków

grudzień 22, 2022How to Choose Materials for Wall and Foundation Waterproofing

Selecting the right construction and waterproofing materials is no simple task. It's best to consult a specialist who can help you determine the most suitable products for your needs and budget. While cost often correlates with quality, the most expensive options are not always the best choice for every situation.

What Factors Influence the Selection of Waterproofing Materials?

Choosing waterproofing materials on your own should not be based on what your neighbor used or what family members recommend. It's a more complex decision because improperly selected materials can prove ineffective, leading to costly repairs and replacements. These additional costs can be avoided by choosing the right waterproofing products from the start.

Key factors to consider when selecting waterproofing materials include the type and usage of the building or specific room. Different materials are required for exterior and interior applications, as UV exposure can degrade certain products over time. Therefore, the location of the application, along with the type and arrangement of insulation layers, must be taken into account. Climate conditions and soil-water factors (based on soil test results) are also critical. Additionally, the presence of aggressive compounds in soil and water, as well as sanitary requirements, may influence the choice. Proper waterproofing ensures safety, hygiene, and cost savings over the long term.

Selecting Waterproofing Based on the Level of Risk

Water poses a threat to buildings not only in the form of rain, snow, and fog but also through groundwater levels, which can fluctuate throughout the year. If you're uncertain about which type of waterproofing to choose, it's wise to opt for waterproofing that protects against water infiltration rather than just dampness, as it offers superior protection.

Types and Applications of Waterproofing

In previous articles, we discussed various classifications of waterproofing materials, such as:

- By Layer Arrangement: Vertical (external walls, foundation walls) and horizontal (foundations, floors, roofs).

- By Risk Level:

- Damp-proofing (protection against moisture).

- Waterproofing (protection against water exerting hydrostatic pressure).

- By Type:

- Lightweight Waterproofing (protection against moisture penetration).

- Medium Waterproofing (protection against direct rainwater, capillary water, or water seeping into horizontal or vertical barriers).

- Heavy Waterproofing (protection against water exerting pressure).

Focus of This Article

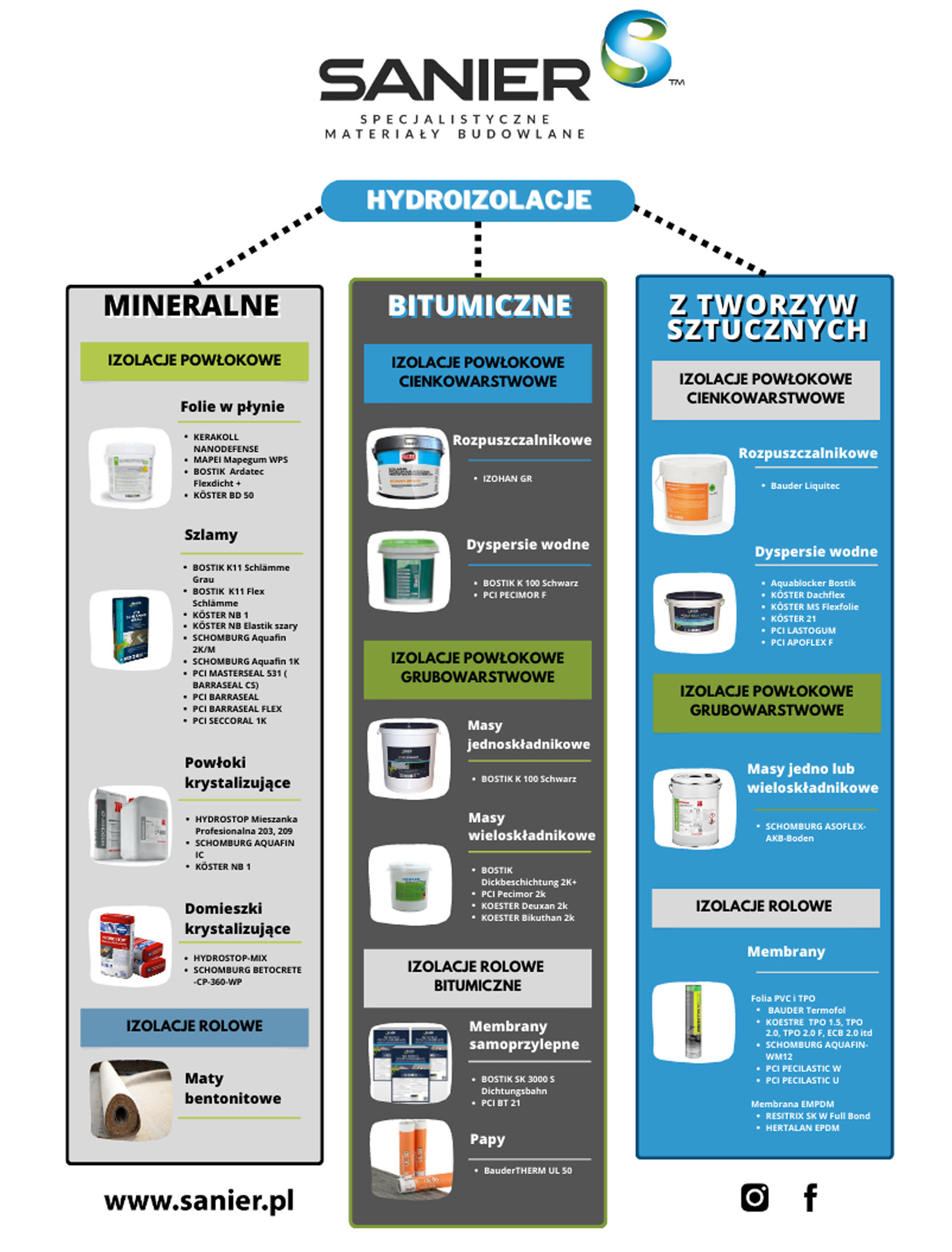

In this guide, we will concentrate on classifying waterproofing products based on the materials they are made from. By understanding these classifications and their uses, you can make an informed decision to ensure the long-term protection and durability of your building.

Mineral Waterproofing Solutions

Mineral liquid membranes are ready-to-use, single-component products. They consist of synthetic resins, which, when exposed to moisture, form a highly flexible waterproof coating.

Features:

- High elasticity

- Easy application

- Crack bridging

- Excellent adhesion to concrete, cement-based mortars, and brick masonry

Applications:

-

Interior use:

- Damp-proofing walls and floors in bathrooms and shower cabins before installing ceramic tile or natural stone coverings.

- Damp-proofing walls and floors in kitchens and on countertops before applying ceramic or natural stone coverings.

Single- or Two-Component Slurries

Slurries are flexible, cement-based coatings that provide waterproofing or damp-proofing depending on the thickness and number of applied layers.

Features:

- Excellent adhesion (even on damp surfaces)

- Elastic properties

- Quick load-bearing capability

- Crack bridging

- Resistant to weak inorganic acids, alkaline solutions, municipal wastewater, and UV radiation (not all products)

Applications:

- Suitable for mineral substrates (concrete, cement, and anhydrite screeds, gypsum plasters, gypsum boards, ceramics) and asphalt substrates.

- Effective for damp-proofing and waterproofing.

- Can be used for positive and negative waterproofing.

- Applicable on deformable and non-deformable surfaces as insulation on the side opposite water pressure.

- Provides sealing against moisture and groundwater (even under pressure) in earth-covered buildings, basements, underground garages, swimming pools, and potable water tanks.

Crystallizing Coatings

Crystallizing coatings are materials designed to seal concrete from within its structure. These products are typically added to concrete as admixtures. They seal or bridge gaps through a chemical reaction, forming a crystalline structure.

Features:

- High adhesion

- Waterproof properties

- Unlimited sealing durability

- Reactivation of sealing ability when exposed to water

- Effective for internal sealing of underground structures

- Vapor permeability

- Compatible with mineral substrates

Applications:

- Used for sealing water tanks, wastewater treatment plants, pumping stations, septic tanks, swimming pools, and underground parts of buildings and structures (e.g., basements, shelters, underground garages).

- Suitable for tunnels, manholes, installation chambers, and wet rooms like baths.

- Applicable in environments with a medium degree of aggressiveness.

- Suitable for residential, industrial, and public utility construction.

- Can be applied internally or externally on structures.

- Used to waterproof concrete and reinforced concrete elements.

- Applicable during the construction phase or for existing structures from the interior.

- Commonly used for sealing foundation slabs, footings, monolithic walls, and reinforced floors.

Bituminous Waterproofing

Thin-layer bituminous coatings are masses based on bitumen-latex emulsions. These products are flexible and create a uniform sealing layer over the surface.

Features:

- Flexible

- Seamless application

- Suitable for surfaces with varying shapes

- Easy to apply

- May contain adhesion enhancers to improve bonding

- Often usable on slightly damp substrates

Applications:

- Vertical and horizontal damp-proofing insulation

- Primer for thick-layer bituminous waterproofing (KMB coatings)

Thick-layer bituminous coatings modified with polymers (KMB) are single- or multi-component products that are odorless and solvent-free. They provide excellent protection against rainwater and groundwater, making them ideal for heavy-duty waterproofing.

Features:

- Odorless

- Solvent-free

- Single-component coatings become water-resistant after complete drying

- Two-component coatings cure without air exposure and/or in the presence of water

- Flexibility that bridges cracks up to approximately 5 mm

Applications:

- Waterproofing construction elements in contact with soil (e.g., foundations, basement walls)

- Vapor barrier layer in waterproofing systems for balconies, terraces, flat roofs, and green roofs

Roll-on bituminous waterproofing includes self-adhesive membranes and roofing felt. Self-adhesive roofing felt can serve as a final layer, while membranes consist of self-adhesive bitumen laminated with an HDPE film on top. Self-adhesive roofing felt is reinforced with a glass mesh base.

Features:

- Easy and watertight joint connections

- Quick application

- Immediate waterproofing after installation

- Non-breathable (non-vapor-permeable)

Applications:

- Vertical and horizontal waterproofing

- Vapor barrier layer in waterproofing systems for balconies, terraces, flat roofs, and green roofs

Liquid Plastic Membranes

Features:

- High water resistance

- Bridges cracks up to 1 mm wide

- Elastic and stretchable

- Seamless and joint-free application

- Fully cures within 24 hours

- Excellent adhesion to mineral substrates

- Vapor-permeable

- Not resistant to acids, alkalis, oils, and solvents

Applications:

- Can serve as a final layer with appropriate finishes (anti-slip coatings, decorative chips, or other designs depending on the manufacturer).

- Suitable for application on concrete substrates, cement screeds, brick masonry with full joints, cement and lime-cement plasters, as well as gypsum plasters, gypsum boards, and wood-based panels.

Roll-On Plastic-Based Waterproofing

Features:

- Durable

- Easy to install

- Versatile range: includes flat films, membranes, dimpled sheets, made from polyethylene or polyvinyl chloride (PVC)

Applications:

- Damp-proof surface protection and vapor barriers under roof coverings

- For creating damp-proof and waterproof insulation of foundations