PVC Membrane

sierpień 27, 2021

Gypsum

sierpień 27, 2021TPO/FPO Membrane

TPO/FPO membrane is used for protecting roofs, terraces, and balconies. It represents a technological advancement over PVC membranes, offering improved performance. Even under extreme temperatures, it does not overheat and remains resistant to atmospheric conditions. It is characterized by high impermeability and long durability, making it an excellent insulation solution. A single layer is sufficient to provide maximum protective properties in all areas exposed to moisture.

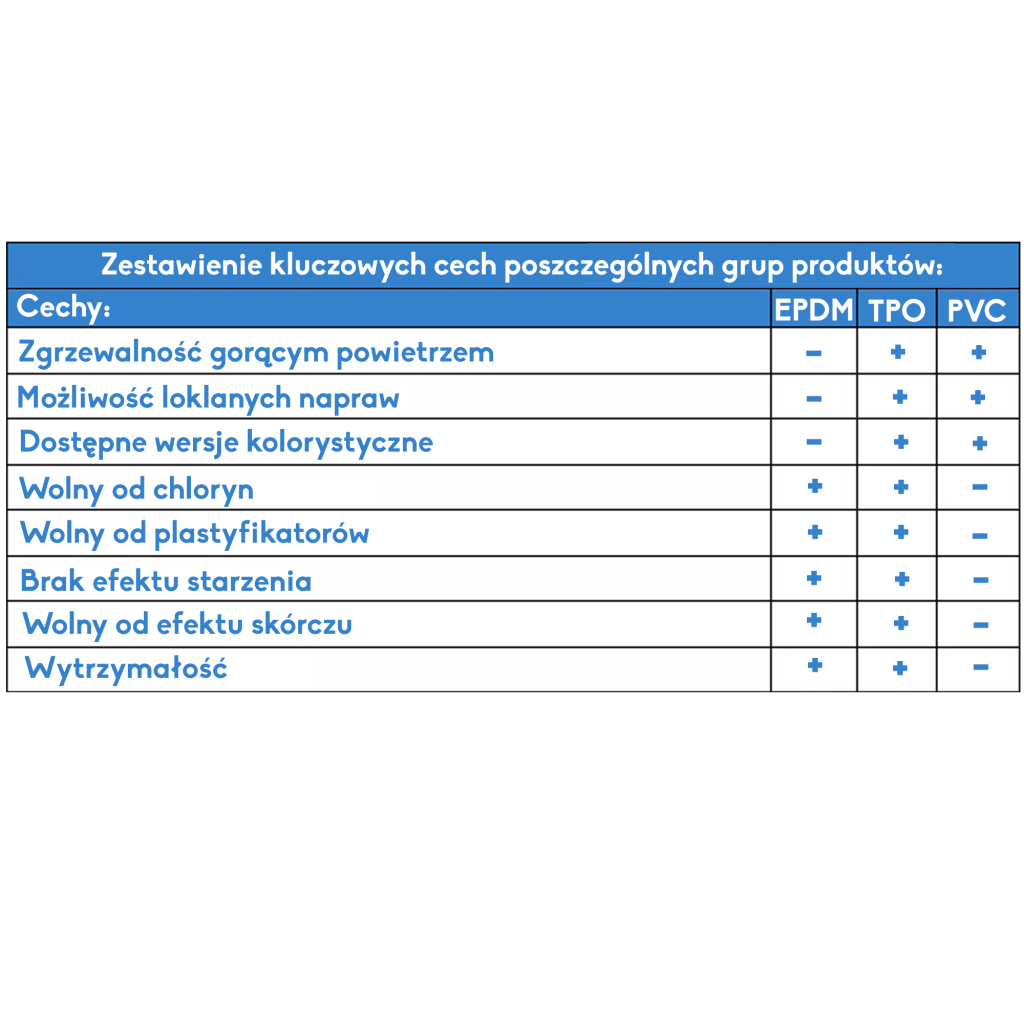

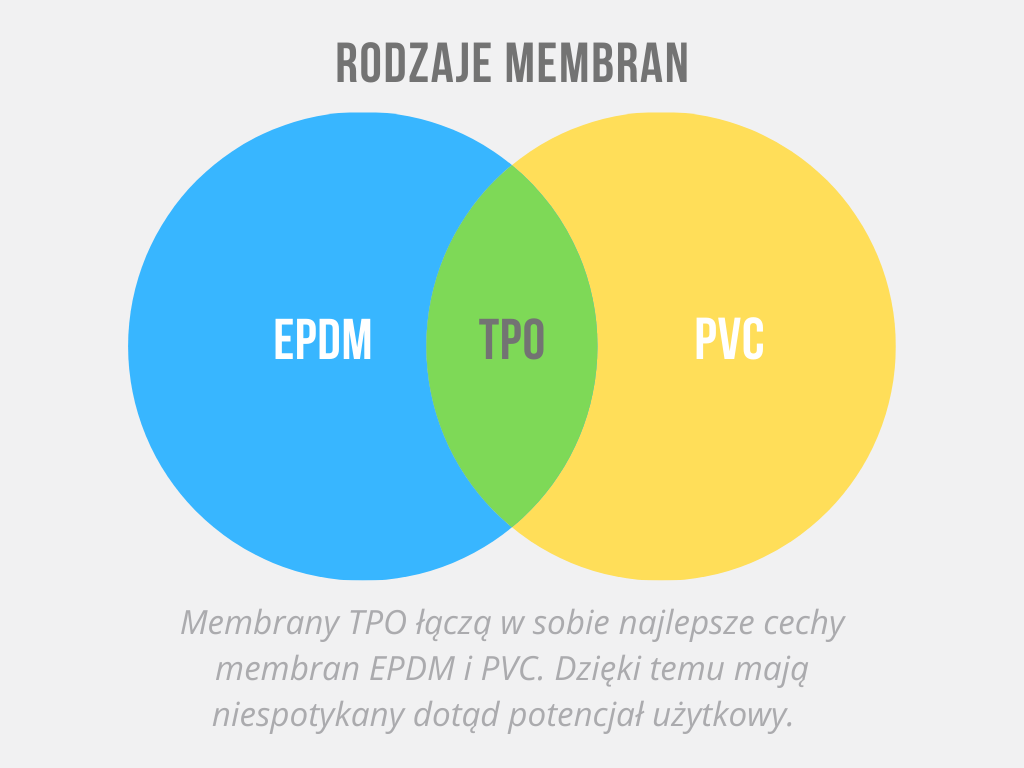

TPO (Thermoplastic Polyolefin), sometimes referred to as FPO (Flexible Polyolefin), is a general term for materials produced from plastic elastomers, drawing from years of experience using EPDM and PVC materials in construction.

A TPO roofing membrane is a combination of synthetic rubber (ethylene-propylene) and polypropylene, sometimes reinforced with a fiberglass mesh. Thermoplastic polyolefins create a flexible material, but one that is less sensitive to extreme high or low temperatures than plasticized PVC.

TPO/FPO membranes do not contain toxins, dioxins, or halogens, making them environmentally friendly, though slightly more challenging to work with. They also exhibit greater durability compared to PVC membranes. Additionally, installation can be performed at lower temperatures, as TPO welding requires only 350°C, whereas PVC requires 550°C. This significantly reduces indirect application costs.

When two TPO/FPO elements are welded, they form a homogeneous structure—the materials melt into each other, creating a permanent, seamless bond. The physical properties of the weld (durability and tear resistance) far exceed the strength of a single membrane layer.

Features of TPO/FPO Membranes

- High durability

- Resistance to aging

- Weather-resistant

- High resistance to prolonged exposure to extreme low and high temperatures

- UV-resistant

- High tensile strength

- Resistance to mechanical damage and punctures

- High resistance to chemical compounds

- Root and microorganism penetration resistance

- High vapor permeability

- Low welding temperature (350°C)

- No need for a separation layer – compatible with all materials

- Easy and durable installation (mechanical fastening or adhesive bonding)

- Flexible and adaptable to structural movements

Applications of TPO/FPO Membranes

- Flat roofs

- Green roofs

- Balconies

- Terraces

- Waterproofing of underground building structures

- Suitable for all installation methods: mechanical, welded, and chemical bonding

KÖSTER TPO/FPO Membrane 1,5 mm

KÖSTER TPO/FPO Membrane 2,0 mm

KÖSTER TPO/FPO PRO Membrane 1,5 mm

Want to Learn More?

Find detailed information about the waterproofing process in our expert guide:

Part 1 – Click Here to Learn More

Part 2 – Click Here to Learn More

Our team of specialists is ready to assist you! If you have any additional questions, call us at +48 533 343 595.