The Perfect Interior Paint

April 4, 2022

Baumit IonitColor Paint

April 27, 2022Why Is Waterproofing a Building Important?

Water is an essential element for life, but it is also a destructive force. Along with air, it is one of the main threats to our homes. Properly executed waterproofing of underground parts of the building and the roof ensures the durability of the structure and long-term safety.

Unfortunately, water is not the only threat when it comes to building foundations. Although it may not be visible at first glance, water contains dissolved organic compounds from decomposition processes, as well as various mineral salts from soil and fertilizers. The presence of salts in water leads to an increase in the volume of building materials over time, eventually causing their degradation.

Another destructive factor is the cyclic freezing and thawing of water, which negatively affects hollow blocks, bricks, plaster, and paint coatings—literally breaking apart building materials from within.

These are just some of the reasons why investing in high-quality waterproofing materials and proper foundation protection technology is essential. Trying to save money on materials often results in significant financial losses in the long run.

Waterproofing is a necessary protective element for various parts of a building that are exposed to prolonged moisture or groundwater infiltration. In the future, this can have negative consequences not only for the building itself but also for our safety and health. Waterproofing is applied to foundations, foundation walls, terraces, floors, and roofs.

Bituminous Waterproofing

One of the most commonly used waterproofing materials is bituminous coatings. They are likely chosen due to their numerous advantages. Unlike roofing membranes and foils, bituminous coatings prevent water from seeping underneath, ensuring a seamless protective layer. Bituminous waterproofing can also be easily applied to slightly damp surfaces. It effectively integrates detailed elements, such as pipe penetrations, with surface waterproofing. Additionally, bituminous coatings are known for their ease of application.

Effective waterproofing should be selected based on soil type, building type, and groundwater levels. When planning a house, it is advisable to conduct a geotechnical soil analysis. This assessment helps determine the appropriate type of waterproofing required. At this stage, consulting a specialist can be beneficial in selecting the right materials and techniques. Taking these steps can help prevent future costs and time-consuming repairs associated with fixing inadequate waterproofing or drying out damp walls.

Light waterproofing is suitable for highly permeable soils, but in other cases, it is safer to opt for heavy-duty waterproofing, which offers protection even against water under pressure.

How to Apply Bituminous Waterproofing on Your Own

The first step is to prepare the surface. Reinforced concrete foundation walls must be sanded to remove cement laitance using wire brushes or wire brush heads. Fresh (2-4 days old) reinforced concrete can be washed with high-pressure water to remove cement laitance—conducting a pressure test will help determine the appropriate pressure level for this process.

Be mindful of sharp edges, as they may damage the waterproofing coating. We recommend rounding the corners of the slab and walls to minimize stress on the waterproofing layer.

The cleaned substrate should be leveled using a repair mortar. The surface to which the mortar will be applied should be matte-damp.

Creating a Fillet on Slab-Wall and Wall-Wall Joints

Next, a fillet should be created at the slab-wall and wall-wall connections using repair mortar. This can be done with a bottle or pipe with a diameter of approximately 10 cm. Before forming the fillet, the surface must be moistened with water to achieve a matte-damp state.

The substrate is then primed using a bituminous material suited to the type of waterproofing being applied.

Applying the Waterproofing Layer

The first waterproofing layer should be applied at an average wet thickness of 2.4 mm. The thickness must be controlled using a gauge at least once per 10 m². When mixing, add the powdered component in small portions to prevent lumps—mix for approximately 2-3 minutes with a slow-speed mixer after fully incorporating the powder into the bitumen.

After the first layer has completely dried, apply the second waterproofing layer, also at an average wet thickness of 2.4 mm. Thickness requirements vary depending on whether medium or heavy-duty waterproofing is being applied.

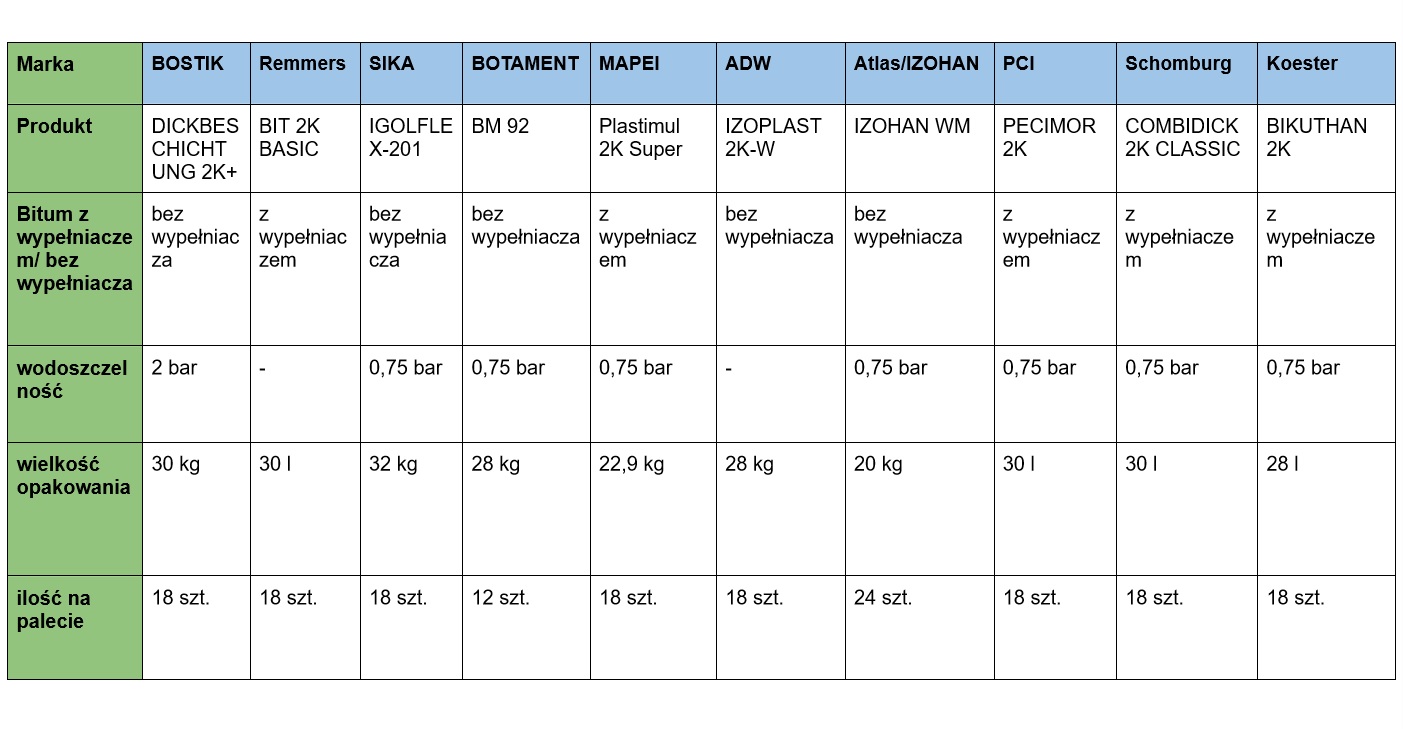

List of Products for Bituminous Waterproofing:

Products available at our physical store in Krakow

For ordering a product not available on sanier.pl, please contact us at: +48 697 691 472 or +48 883 292 303

SANIER recommends the following bituminous waterproofing products:

Bostik Dickbeschichtung 2K+

PCI Pecimor 2k

Koester Bikuthan 2K

Koester Deuxan 2K

Schomburg Combidick 2K Classic

Schomburg Combidick 2K Premium

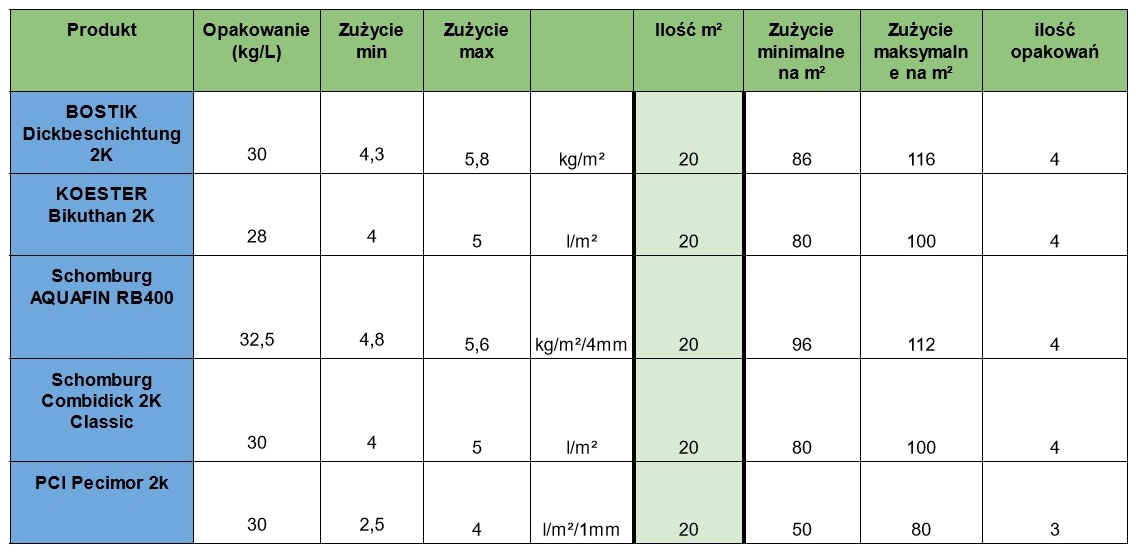

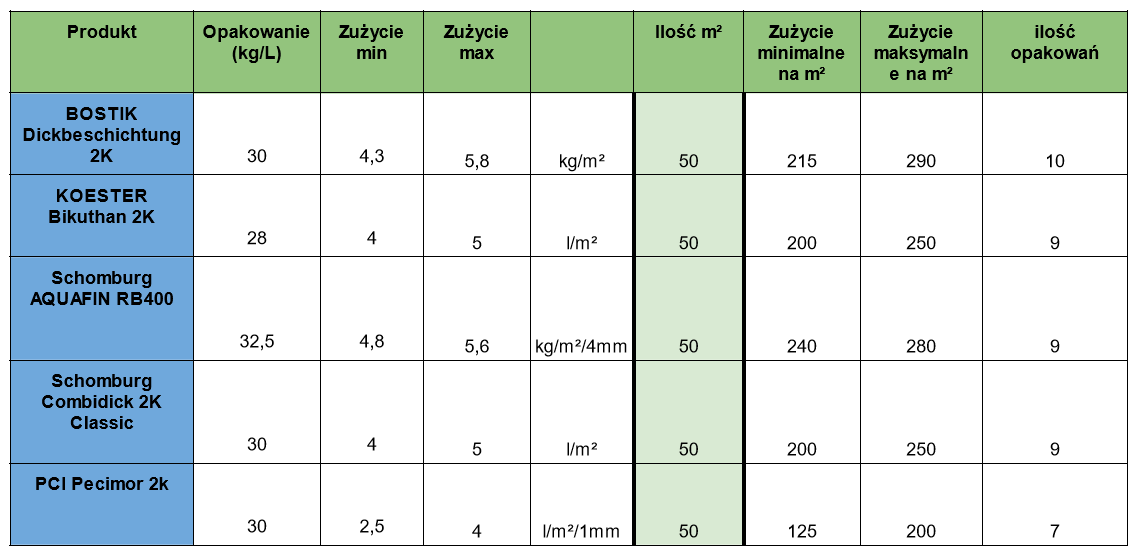

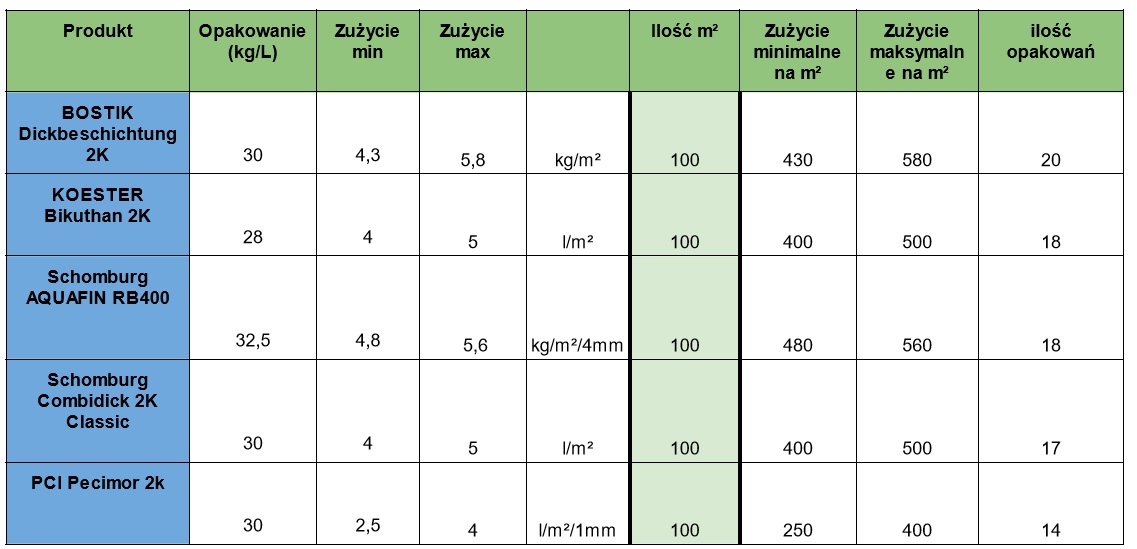

Table of Material Consumption for Selected Bituminous Waterproofing Products per m²

Consumption of materials for: 20 m², 50 m², 100 m²

Want to Learn More?

Detailed information on the waterproofing process can be found in our guide:

Part 1 – Click and Check

Part 2 – Click and Check

Need Expert Advice? Our team of professionals is happy to assist you. If you have any questions, call us at: 533 343 595