Formwork - Shuttering

sierpień 18, 2023

Facade

październik 2, 2023Dysperbit

Dysperbit is a commonly used material for damp-proofing foundation walls. Produced by various manufacturers under the same name, its primary components include water, asphalt emulsions, and rubber. The key element is post-petroleum asphalt modified with synthetic rubber. Additionally, emulsifying agents and compounds that lower the freezing point of water, known as corrosion inhibitors, are integral parts of this mixture.

It is currently one of the most widely used products for foundation waterproofing, though not necessarily the most effective. Dysperbit primarily serves as a moisture barrier, preventing ground moisture from penetrating structures. However, it does not offer effective protection against flowing or pressurized water. It lacks UV resistance, has low elasticity, and may crack during drying, especially when applied in thick layers. Dysperbit has a long curing time, and exposure to water can cause it to wash away or form white efflorescence.

Despite its low cost and ease of application, Dysperbit has several significant drawbacks, such as:

- Lack of full water resistance

- Low elasticity

- Susceptibility to UV damage

- Shrinkage during drying

- Limited vapor permeability

This means Dysperbit does not meet the requirements for comprehensive waterproofing.

Even when used with dimpled membrane foil, Dysperbit does not provide sufficient waterproofing. Proper foundation protection is essential to prevent heat loss, moisture problems, and mold growth. Mistakes at this stage can be difficult and costly to fix. In recent years, awareness among investors has increased. More people now understand that painting foundation walls black with Dysperbit and applying dimpled foil is insufficient for effective waterproofing.

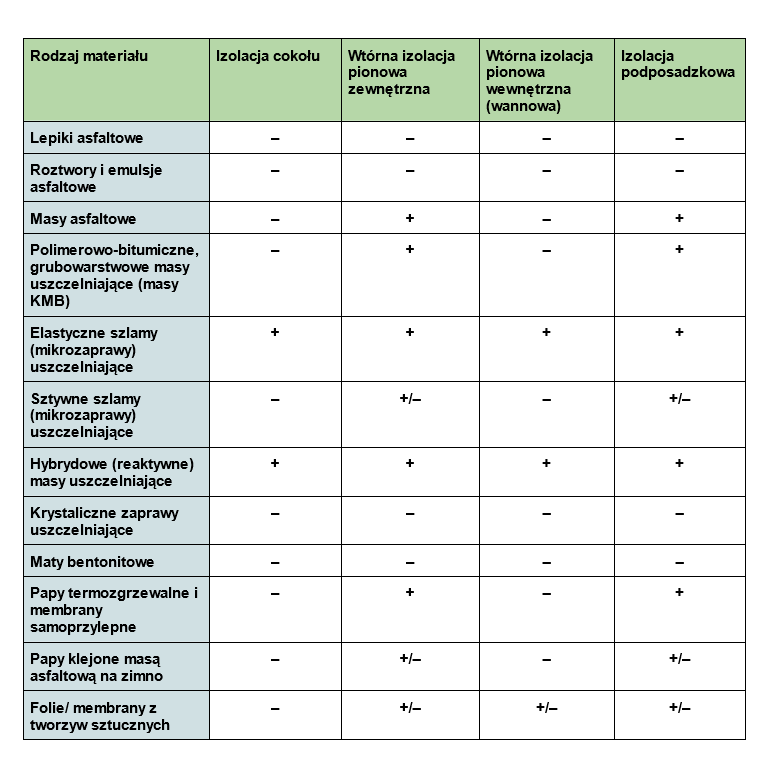

For a truly effective foundation waterproofing solution, it is worth considering more advanced materials. The market offers various waterproofing products that provide comprehensive protection against moisture and water. Key steps include analyzing the soil type and selecting the appropriate waterproofing technology. Available options include:

- Bituminous materials (solutions, emulsions, coatings, and asphalt adhesives)

- Mineral materials (bentonites, micro-mortars)

- Hybrid materials (combining the advantages of bituminous and mineral waterproofing)

- Synthetic materials (foils, membranes, and polymer-based waterproofing compounds)

Waterproofing foundations does not have to be excessively expensive or complicated if the right materials and techniques are used. Careful analysis and selection based on specific needs are essential. Reliable information sources and expert consultation can ensure effective and long-lasting waterproofing.

How to Waterproof Foundations?

The first step is selecting the right waterproofing material.

The modern market offers a variety of waterproofing materials that effectively protect underground building components from water damage. Thanks to innovative technologies, these materials have unique properties, making them suitable for different conditions. Additionally, their application is quick and easy.

There are several types of waterproofing materials to choose from, including:

- Bituminous materials (solutions, emulsions, coatings, and asphalt adhesives, as well as polymer-bitumen sealants like KMB coatings and bituminous membranes)

- Mineral materials (such as bentonites and micro-mortars)

- Hybrid materials (next-generation sealants that combine the benefits of bituminous and mineral waterproofing)

- Synthetic materials (including foils, membranes, polymer dispersions known as "liquid foils," and resin-based coatings)

Which Materials Should Be Used for Foundation Waterproofing?