Why Is Waterproofing Essential?

sierpień 24, 2022

4. Sanier Waterproofing Studio – Soil Testing on Your Property

wrzesień 5, 2022Why Does the Polish "White Tank" Have a Bad Reputation?

The negative reputation of the "white tank" technology in Poland often stems from a lack of comprehensive knowledge among those responsible for its design and implementation. While this is not a universal issue, it frequently leads to the repetition of outdated solutions, which in turn results in complications during later stages of construction. Designers are well-versed in building structures; however, for many, the "white tank" simply represents concrete with a specific strength class. Practically speaking, they focus on the structural calculations and include safety factors. If the foundation interacts with water, they specify "water-resistant" concrete (W8) and consider the technology complete.

Misconceptions About W8 Concrete

It is important to clarify that W8 concrete is not fully waterproof. Additionally, the Polish standard PN-B-06265 no longer includes water-tightness grades. New projects should avoid referencing the "W" parameter, as it is no longer recognized in updated standards. Instead, the focus has shifted to measuring water penetration depth under hydrostatic pressure. This represents a significant change:

- The specifying parties and clients must agree on the maximum allowable depth of water penetration into the concrete, which should typically be less than the protective concrete cover's thickness.

Challenges in Modern Construction

There is a growing trend toward constructing buildings in more challenging terrains and at deeper levels. This has introduced more complex geotechnical and hydrogeological conditions. For example:

- Foundations are now being laid at levels -2 or -3, exposing them to aggressive physical and chemical factors.

- The absence of clear specifications for water resistance in the design phase often results in repeated mistakes, leading to structural degradation, particularly under demanding water-related conditions.

Risks Associated with "White Tank" Construction

The "white tank" is only as strong as its weakest link. Problems can arise at multiple stages:

- Design Phase:

- A separate "white tank" design is required in addition to the general construction plans, but few designers take on this task due to its complexity.

- Contractors often deviate from the original "white tank" design or create their own, increasing the risk of errors.

- Execution Phase:

- Concrete Pouring and Curing: Weather conditions and on-site practices heavily influence success. Improper curing—often dismissed as unnecessary by construction workers—can compromise the structure.

- Reinforcement and Interpretation: Errors in reinforcement placement or misreading the design can lead to structural weaknesses.

- Even high-quality concrete cannot compensate for mistakes in placement, curing, or reinforcement, leading to cracks and leaks.

High Technological Demands

Maintaining strict adherence to technological standards is critical for the success of "white tank" construction. Even minor deviations can compromise its watertightness. However, the technology does have one advantage: leaks are relatively easy to locate. For example:

- Water seeping from a corner clearly indicates the problem area, unlike systems with external waterproofing layers. In such cases, water can infiltrate between the coating and the concrete, meander within the structure, and emerge far from the actual source of the problem, making leaks challenging to locate.

Conclusion

The "white tank" technology offers significant potential when executed correctly but demands precision at every stage of the project. Ensuring proper design, execution, and maintenance is essential to prevent common issues and maximize the benefits of this advanced construction method.

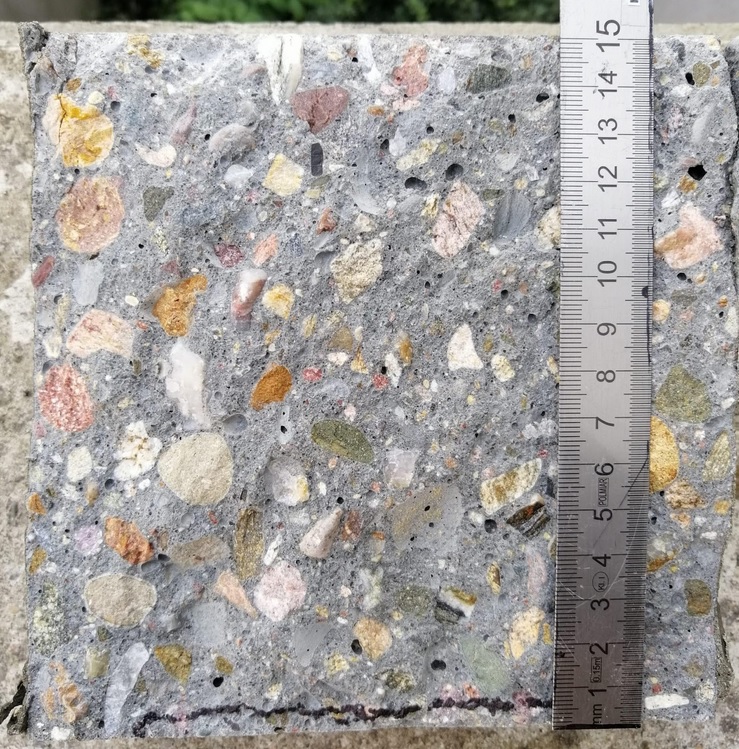

Concrete with BETOCRETE-C Additive (Maximum Penetration Depth – 8 mm)

“White Tank” Technology on a Standard Foundation:

The Schomburg company offers its globally proven "White Tank" hydroisolation system using the BETOCRETE-C crystalline admixture. This admixture supports the self-healing process of shrinkage cracks in concrete, ensuring long-term structural integrity and watertightness.

Ease of Implementation with BETOCRETE-C:

The BETOCRETE-C system simplifies the process of designing and constructing "White Tanks" by providing a complete set of standards for project development.

The external side of the foundation is constructed using watertight concrete in the BETOCRETE-C system, with sealed construction joints at plate-wall, wall-wall, and plate-plate interfaces.

Advantages of the BETOCRETE-C System:

One of the key benefits of this solution lies in its compliance with Eurocode standards, which are stricter than Polish norms. Here's the comparison:

- Polish Norms: Allow for a design crack width of up to 0.3 mm, which can absorb water into the structure.

- Eurocode Standards: Limit the design crack width to 0.2 mm, effectively blocking water ingress.

This seemingly small difference has a significant impact on the durability and watertightness of the structure. Water entering cracks in a 0.3 mm system serves as a carrier for sulfates, CO₂, and chlorides, which can:

- Reach the reinforcing steel,

- Lower the pH of the surrounding concrete,

- Lead to steel depassivation, rapid corrosion, and eventual degradation or spalling of concrete structures.

The Science Behind BETOCRETE-C:

The Eurocode 2 (specifically, “Eurocode 2-- Design of Concrete Structures -- Part 3: Silos and Liquid Retaining Structures,” p. 10) explicitly limits crack widths to 0.2 mm for liquid retaining structures. Adopting this standard ensures significantly improved long-term performance and safety for "White Tank" applications.

BETOCRETE: A Comprehensive "White Tank" System Solution