Decorative Effects: Brick Wall

listopad 25, 2022

How to Waterproof a Well?

grudzień 8, 2022Waterproof Concrete

Hydrostop expert Marek Mularczyk explains the key aspects of waterproof concrete.

Are you considering implementing waterproofing but unsure which materials to choose?

Together with Hydrostop expert Marek Mularczyk, we have prepared a short series dedicated to waterproofing. Here, you’ll find answers to questions such as: What is waterproofing? How is waterproofing done? Is foundation waterproofing necessary? And, what is waterproof concrete?

Waterproof Concrete

For many years, so-called waterproof concrete has been popular in construction. However, during my career, I spent a few months working in a precast concrete plant, and I learned an important truth: concrete is only waterproof when the sample tested has been prepared under ideal conditions. As a young engineer, I was responsible for this process—creating perfect samples, storing them in a controlled, humid environment, and meticulously maintaining them. Unsurprisingly, all test results were excellent.

However, it’s crucial to remember that construction sites are not laboratories. On-site, concrete is exposed to weather conditions over which we have little or no control. So, what happens to waterproof concrete in such conditions? Unfortunately, it often loses its waterproof properties.

What Can Go Wrong in the Technology of Waterproof Concrete?

There are numerous points in the process of creating waterproof concrete where errors can occur, starting from the batching plant to the construction site. Here’s a breakdown of potential issues:

1. At the Batching Plant

- Incorrect Mix Design: Using the wrong concrete recipe or poorly selecting aggregates can compromise the quality.

- Cement-Water Ratio: Errors in the water-to-cement ratio can affect waterproofing properties.

- Logistical Errors: Mistakes in the delivery process, such as sending the wrong mix, can occur.

2. Transportation of Concrete

- Delays in Delivery: Concrete should ideally be placed within 50 minutes of mixing. Traffic delays, such as an hour-long traffic jam, can render the mix unusable and require disposal.

- Adding Water: Workers may add water on-site to improve workability, disrupting the designed water-cement ratio and voiding waterproofing properties.

3. Installation Challenges

- Sealing Gaps: Waterproofing relies on installing sealing tapes in construction joints. Errors such as missing tapes, using the wrong type, incorrect installation, or poor welding of tapes can all lead to leaks.

- Improper Placement:

- Dropping the concrete from excessive heights can cause segregation.

- Over-vibrating or under-vibrating the mix can weaken its uniformity.

- Using a vibrator too short for the height of the wall can leave unvibrated areas, leading to weak spots.

4. Concrete Curing

Placing the concrete is only half the battle. Proper curing is essential to maintain its integrity:

- Dry Conditions: If too dry, the concrete must be watered to maintain the necessary moisture.

- Wet Conditions: If too wet, the surface must be protected from excessive rain.

- Cold Temperatures: In cold weather, the concrete should be heated to prevent freezing before it sets.

Every one of these steps is human-dependent, and mistakes can result in a concrete structure that is no longer waterproof.

The Solution

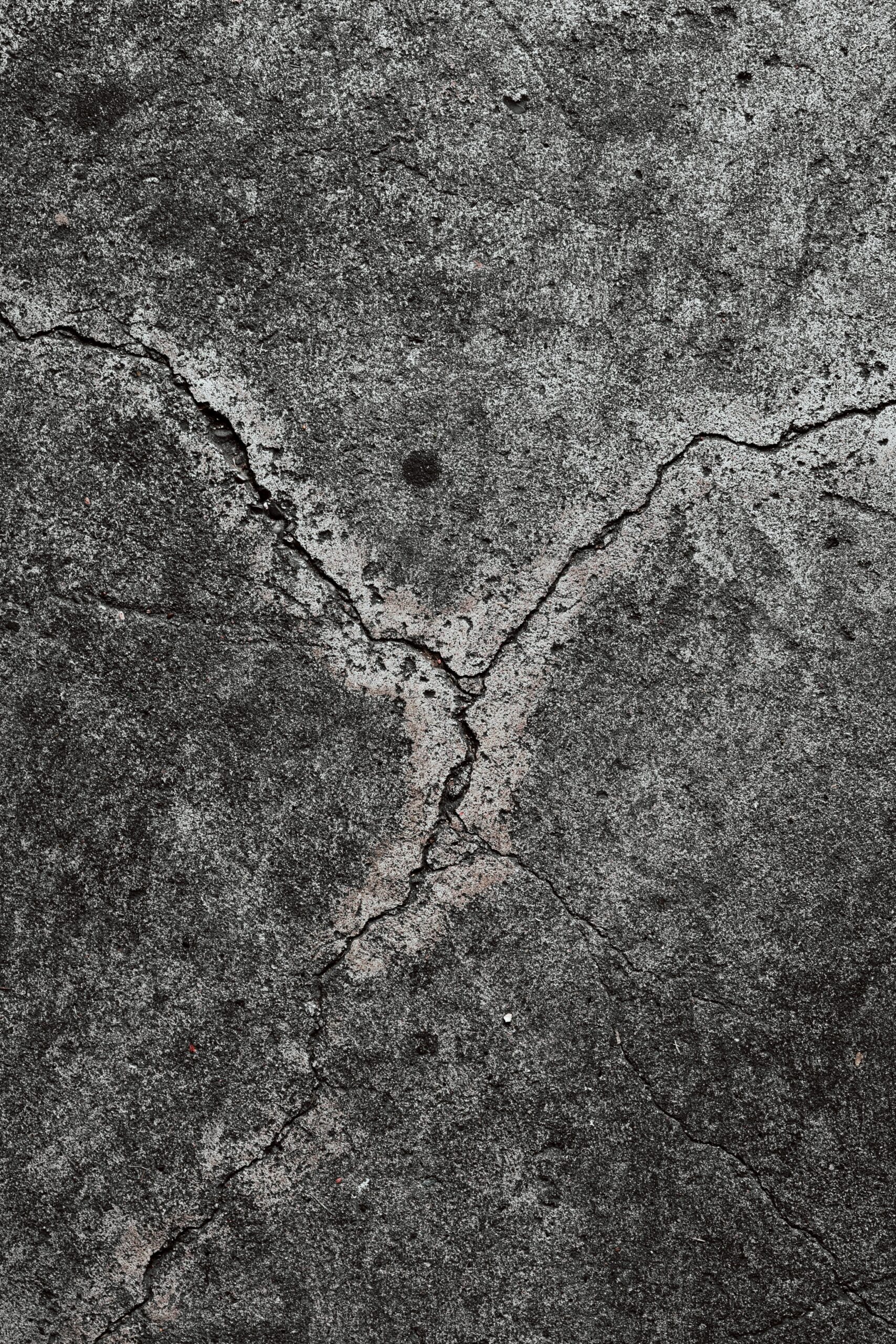

Assume from the outset that concrete alone is not inherently waterproof. Complement the process with mineral materials, such as Hydrostop, which can seal cracks and imperfections. As seen in the accompanying illustration, these materials effectively close gaps that may form. Preparing for potential errors in the execution phase and implementing secondary sealing measures ensures the structure’s long-term waterproofing integrity.